HOME > News > Industry News > Bid farewell to manual errors. The dynamic batching machine for cow, sheep and pig manure makes prod

HOME > News > Industry News > Bid farewell to manual errors. The dynamic batching machine for cow, sheep and pig manure makes prod Update time : 2025-02-28 Publisher:Zhengzhou Hanke Machinery

In industrial production, batching errors not only lead to unstable product quality but also may cause raw material waste and an increase in production costs. Traditional manual batching methods, influenced by human factors, have a relatively high error rate and are difficult to meet the high standards of modern production. The dynamic batching machine for cow, sheep and pig manure provides enterprises with a precise and reliable solution.

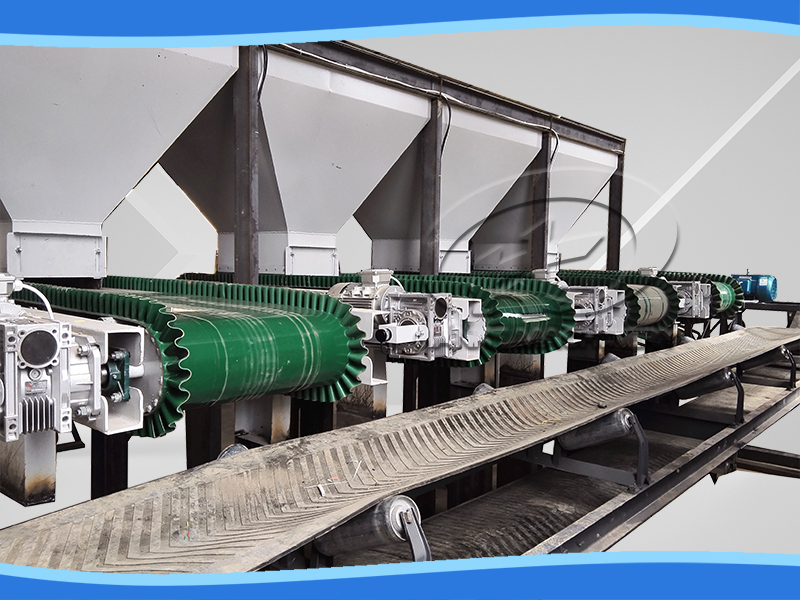

The dynamic batching machine for cattle, sheep and pig manure is a specialized equipment designed for handling and batching cattle, sheep and pig manure. Its main function is to add multiple materials into the mixing hopper according to the weight values set by the user based on the specified formula. The dynamic batching machine for cattle, sheep and pig manure is widely used in various industries, including but not limited to chemical, fertilizer, plastic, rubber, wire and cable, cement, dry-mixed mortar, concrete, asphalt, ceramics, glass, metallurgy, mining, power, grain, feed, flour and other industries dealing with powder and granular materials and liquid materials.

The dynamic batching machine for cattle, sheep and pig manure adopts high-precision sensors and dynamic compensation algorithms, which can monitor and adjust the weight and proportion in the batching process in real time, ensuring that the raw material ratio of each batch reaches the optimal state. Compared with traditional manual batching, the error rate is reduced from ±2% to ±0.2%, significantly improving the consistency of product quality.

Advantages and features of the dynamic batching machine for cow, sheep and pig manure

1. Quality improvement in production: The use of this equipment can enhance the packaging of organic fertilizers, inorganic fertilizers, etc., ensuring superior packaging quality and thereby increasing the profits of enterprises.

2. Precise measurement: Capable of weighing, counting, etc., reducing the number of rework times and improving production efficiency.

3. Wide application range: It is applicable to multiple fields such as chemical engineering, agriculture, food, and industry.

4. Fast speed: It can package over a hundred bags per hour. The specific speed may vary depending on the packaging range.

5. Labor saving: Only two workers are needed for one production line, one for bag loading and the other for adjusting the bag opening during sealing. This saves enterprise costs and improves production efficiency.

6. Easy operation: It adopts PLC control and is equipped with a touch screen human-machine interface control system, which is easy to operate.

7. High degree of automation: The entire process of weighing and packaging is unmanned, and it has an automatic detection function. For instance, if the bag is not opened or not fully opened, no material will be added and no heat sealing will be performed. The bag can be reused, and no material will be wasted.

The dynamic batching machine for cow, sheep and pig manure, with its high precision and intelligent features, is becoming the preferred solution for an increasing number of enterprises. If you also wish to bid farewell to manual errors and achieve precise production, the dynamic batching machine for cow, sheep and pig manure from Hanko Machinery will be your ideal choice!

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.