HOME > News > Industry News > Features, application scenarios and selection of 525 Organic Fertilizer Dynamic Batching Scale

HOME > News > Industry News > Features, application scenarios and selection of 525 Organic Fertilizer Dynamic Batching Scale Update time : 2025-05-23 Publisher:Zhengzhou Hanke Machinery

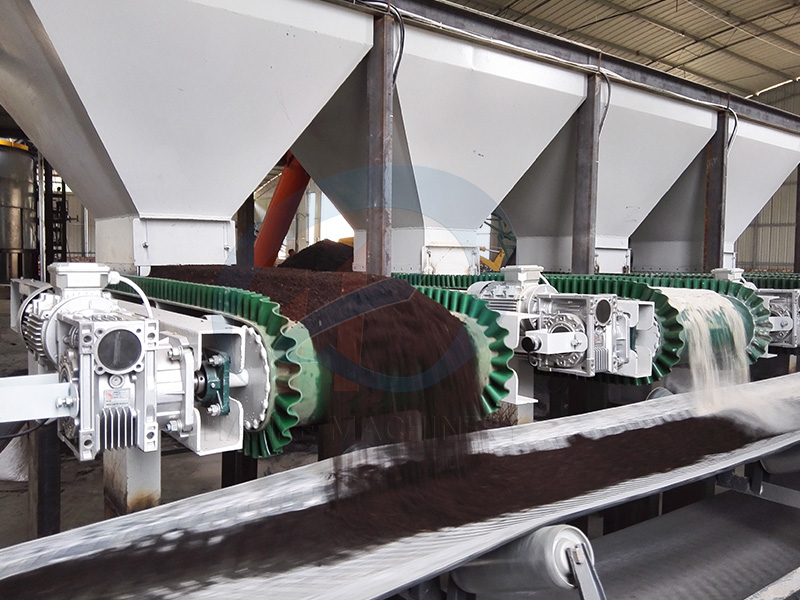

The 525 organic fertilizer dynamic batching scale is mainly used in organic fertilizer production lines to achieve the proportioning of livestock and poultry manure and auxiliary materials, the control of the mixing ratio of different raw materials, and the quantitative packaging of finished fertilizers, ensuring the stability of the fermentation and granulation processes. The following is a detailed explanation from three aspects: equipment features and advantages, application scenarios, and selection suggestions:

I. Features of the 525 Organic Fertilizer Dynamic Batching Scale Equipment

Dynamic continuous batching: By adopting dynamic metering technology, it realizes the continuous and real-time batching of various raw materials.

High-precision measurement: The measurement accuracy of dynamic batching scales is usually better than 1.0%, and some high-end equipment can reach 0.5%, which can meet the strict requirements for raw material ratios in organic fertilizer production.

Multi-bin design: The equipment supports multi-bin batching (such as three-bin, four-bin, and five-bin), capable of simultaneously processing various raw materials (such as nitrogen, phosphorus, potassium fertilizers, and organic materials), achieving continuous and dynamic quantitative transportation.

Intelligent control: Equipped with a PLC control system and PID regulation function, it can monitor the material flow and proportioning deviation in real time, automatically adjust the belt speed or discharge volume, and ensure production stability.

Strong adaptability: According to the characteristics of the material (such as fluidity, moisture content), the screw type, belt type or U-shaped conveying method can be selected to adapt to different forms of raw materials such as granular and powdered.

Ii. Application Scenarios of 525 Organic Fertilizer Dynamic Batching Scale

Organic fertilizer production line: It is used for the mixing and proportioning of raw materials such as livestock and poultry manure, straw, and sludge, ensuring the stability of the fermentation and granulation processes.

Compound fertilizer production: Supports precise blending of basic elements such as nitrogen, phosphorus and potassium to meet the requirements of different formulas.

BB fertilizer (blended fertilizer) production: Achieve dynamic proportioning of multiple raw materials to enhance the production efficiency and product quality of blended fertilizers.

Iii. Suggestions for Selecting 525 Organic Fertilizer Batching Scale

Select the number of warehouses based on the production scale

Small and medium-sized organic fertilizer factories: It is recommended to choose a 3-bin dynamic batching scale (main material bin + auxiliary material bin + microbial agent bin) to meet the requirements of the NY 525-2021 standard.

Large-scale continuous production line: It is recommended to choose a combination of 4 dynamic compartments and 2 static compartments to achieve dynamic weighing of manure and straw as well as static addition of microbial agents.

Finally, as a professional manufacturer of automatic quantitative packaging machines, Zhengzhou Hanke Machinery suggests: If there is a high requirement for proportioning accuracy (such as the addition of bacterial agents), it is recommended to choose a static batching scale. If it is necessary to handle bulk raw materials (such as livestock and poultry manure), it is recommended to choose a dynamic batching scale to improve efficiency. Reserve one spare warehouse for future use when increasing the types of raw materials or adjusting the formula.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.