HOME > News > Industry News > Why choose the dynamic batching scale for light substrate seedling cultivation? What are its advanta

HOME > News > Industry News > Why choose the dynamic batching scale for light substrate seedling cultivation? What are its advanta Update time : 2025-07-14 Publisher:Zhengzhou Hanke Machinery

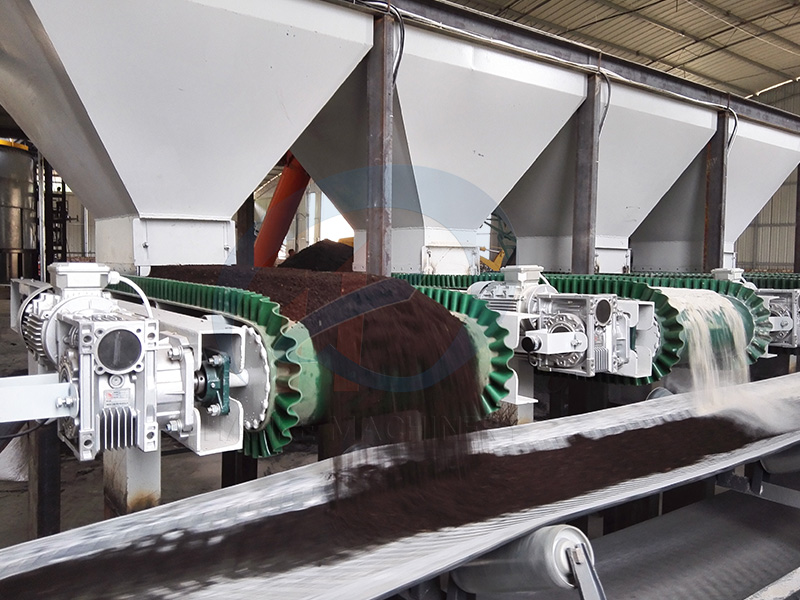

The light substrate seedling dynamic batching scale is a device that integrates conveying, weighing and quantitative control. It can meet the requirements of continuous batching and can dynamically weigh and batch multiple materials according to the preset proportion. The following is an introduction to the parameters, advantages and manufacturers of the light substrate seedling dynamic batching scale.

I. Main Parameters of Dynamic Blending Scale for Lightweight Substrate Seedling Raising

Take the dynamic feeding belt scale as an example, its main parameters are as follows:

Working mode: Continuous automatic

Working voltage: 380VAC ± 10%, 50Hz ± 2Hz

Single bin external dimensions: 2000/1100/500 (length/width/height)

Single-bin batching capacity: 2-9 t/h (can work independently or in combination with multiple bins)

Basic configuration: main unit, hopper, sewing machine, column, 3-meter conveyor

Applicable objects: Material batching, as well as material flow rate, cumulative quantity, monitoring, etc.

II. Advantages of Dynamic Ingredient Weighing for Lightweight Substrate Seedling Raising

1.Improve production efficiency

Dynamic batching scales can achieve continuous batching. During the material conveying process, weighing and batching operations are completed simultaneously, eliminating the need for frequent intermittent operations such as loading, weighing, and unloading as in static batching. This significantly saves time and enhances production efficiency. For instance, in continuous production sites such as sintering batching and coking batching, dynamic batching can meet the continuous requirements and does not allow for any interruption in the batching process.

2. Ensure the accuracy of ingredient measurement.

Through advanced sensors and control systems, dynamic batching scales can monitor the flow and weight of materials in real time and make precise adjustments according to the set ratios. Dynamic feeding belt scales and 150-kilogram dynamic drum scales both adopt high-precision weighing sensors, which can effectively reduce measurement errors and ensure the stability of product quality.

3. High degree of automation

It can be linked and controlled with other equipment on the production line to achieve the automation of the entire production process. Operators only need to set the batching parameters, and the equipment can automatically complete the batching tasks, reducing manual intervention, lowering labor intensity, and also minimizing the impact of human factors on batching accuracy.

III. Brand Recommendations for Dynamic Blending and Weighing Equipment for Lightweight Substrate Seedling Raising

There are some relatively excellent dynamic batching scale brands in the market, such as Zhengzhou Hanko Machinery Factory. It has accumulated many years of experience and technology in the packaging industry, and the packaging equipment it has sold has received the trust of many people. The newly launched light substrate seedling dynamic batching scale has also seen an increase in sales. Users with the need for granular packaging production can consult online to learn more.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.