HOME > News > Industry News > When purchasing a fertilizer dynamic batching machine, how to judge its quality?

HOME > News > Industry News > When purchasing a fertilizer dynamic batching machine, how to judge its quality? Update time : 2025-08-27 Publisher:Zhengzhou Hanke Machinery

When purchasing a dynamic fertilizer batching machine, it is necessary to comprehensively evaluate the quality from multiple dimensions such as the core performance of the equipment, key components, process adaptability, and brand service to avoid issues like poor batching accuracy and high failure rates due to equipment problems, which could affect the efficiency of fertilizer production and product quality. The following are specific judgment criteria:

I. Core Performance: Focusing on "Measurement Accuracy" and "Operational Stability"

The core value of the batching machine lies in precise proportioning. These two performances directly determine the quality grade of the equipment and need to be verified first.

Actual measurement of metering accuracy

Precision is the lifeline of fertilizer blending (especially for products like BB fertilizers and compound fertilizers that have strict requirements for nutrient ratios), and it needs to be judged through both "static" and "dynamic" double tests.

Static accuracy: When the equipment is unloaded, the sensor zeroing error should be ≤ 0.1%. When loading standard weights (such as 50kg, 100kg), the displayed weight deviation from the actual weight should be ≤ 0.2% (for high-quality models, it can reach 0.1%).

Dynamic accuracy: Simulate actual production conditions (such as conveying granular and powdered fertilizers), and run continuously for more than 30 minutes. Record the deviation between the weight of each batch of ingredients and the set value. For high-quality models, the dynamic error should be ≤ 1.0%, and for ordinary models, it should be ≤ 2.0% (if the deviation exceeds 3%, it will lead to non-compliance of fertilizer nutrients and quality inspection risks).

Tips: Request the manufacturer to provide a third-party metrological testing report (such as a National Metrological Accreditation CMA report) to avoid "verbal promises".

Observation of operational stability

Check the "uniformity of feeding": when conveying granular materials, there should be no "material interruption or surging", and for powdered materials, there should be no "bridging or clogging" (you can observe whether the equipment is equipped with anti-clogging stirring paddles or vibration arch-breaking devices; high-quality models will optimize the structure in consideration of the tendency of fertilizers to form lumps).

Look at "load adaptability": When the feed rate is adjusted within the range of 80% to 120% of the rated output, the equipment should respond quickly (for instance, the lag of frequency converter speed regulation should be no more than 1 second), without any "overshoot or undershoot" phenomenon (if it takes more than 3 seconds to stabilize after adjustment, it will cause batch batching deviation).

Look at the "continuous operation failure rate": Ask the manufacturer to provide actual user cases (such as equipment used in a fertilizer factory for over one year), and inquire about the "average monthly failure times" (for high-quality models, it should be no more than 1 time, and the maintenance time for failures should be no more than 2 hours to avoid production disruption due to machine downtime).

II. Process Compatibility: Avoid Mismatch between "Universal Models" and "Actual Requirements"

The type of fertilizer (granular / powdered / paste-like), output, and complexity of the formula vary greatly, which leads to significant differences in the requirements for batching machines. It is necessary to determine the "compatibility" based on one's own production needs rather than blindly choosing "high-end models".

Material property compatibility

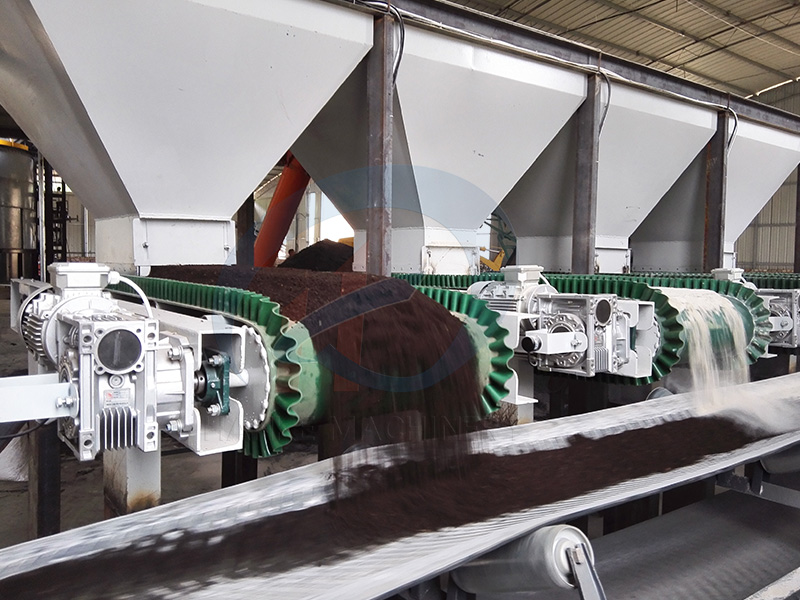

If the ingredients are granular fertilizers (such as organic fertilizer granules or compound fertilizer granules), it is necessary to confirm that the feeder is of the "belt type" or "screw type" (the belt type is more suitable for non-sticky granules to avoid crushing by screw pressure), and the surface of the belt needs to be anti-slip (such as adding patterns) to prevent granules from slipping and causing inaccurate measurement.

If the ingredients are powdered fertilizers (such as monoammonium phosphate, potassium fertilizer powder), "double-screw feeding" should be selected (to avoid single-screw bridging), and a "dust removal interface" should be equipped (to connect to the workshop dust removal system and reduce dust pollution). At the same time, the sensor needs to be "anti-interference shielded" (to prevent dust adhesion from affecting the signal).

If the ingredients are a mixture of materials (such as granules + powder): It is necessary to confirm whether the equipment supports "independent control of separate compartments" (different materials use different feeding devices to avoid cross-contamination), and the batching sequence can be customized (for example, add granular materials first and then powder materials to reduce dust adhering to the surface of granules).

Output and formula compatibility

Output matching: The rated output of the equipment should be 20% higher than the actual demand (for example, if 1 ton of ingredients is needed per hour in practice, choose a model with a capacity of 1.2 tons per hour to avoid full-load operation that accelerates wear and tear).

Formula complexity: If more than three materials need to be mixed simultaneously (for example, BB fertilizers often require 5-6 raw materials), the number of batching bins needs to be confirmed (at least 3 bins, and high-quality models can be expanded to 6 bins), and each bin's feeder can be independently adjusted (to avoid "one bin failure, the entire line stops").

III. Brand and Service: Avoiding the Risk of "No After-sales Guarantee"

1.Brand selection

Give priority to "specialized brands for the fertilizer industry" (such as Henan Tongda, Jiangsu Kerun, and Shandong Yuguang), rather than "general-purpose batching machine manufacturers" - these brands have a better understanding of fertilizer characteristics (such as corrosiveness and caking), and their equipment structures are more in line with industry requirements (such as optimized sealing designs for dust in fertilizer workshops).

Avoid "small workshop manufacturers": You can check the manufacturer's establishment years (suggested to be ≥ 5 years), registered capital (≥ 5 million yuan), and whether they have a "fertilizer equipment production license" through "Qichacha" or "Tianyancha" to reduce the risk of "going out of business after purchase and no after-sales service".

2. After-sales Service Verification

Check the "Service Scope": Does it offer "On-site Installation and Commissioning" (the batching machine needs on-site calibration, and remote guidance is prone to errors), and "Free Technical Training" (to ensure operators can calibrate, adjust recipes, and handle common faults).

Check the "warranty period": The warranty for core components (such as sensors, controllers, and motors) is no less than 1 year (up to 2 years for high-quality brands), and the warranty for the entire machine is no less than 6 months. Also, clearly state the "replacement price and cycle for consumable parts (such as belts and sealing rings)".

Check "Emergency Response": Inquire about "After-sales phone response time" (which should be ≤ 2 hours) and "Distribution of nearby service points" (if the manufacturer has service points in the local area, fault repair can be completed on the same day, avoiding downtime exceeding 24 hours).

IV. On-site Inspection: "On-site Machine Testing" if necessary

If the purchase amount is ≥ 50,000 yuan, it is recommended to go to the manufacturer or a nearby user's site for a trial run, with a focus on observing:

"Blending accuracy" in actual production: Ask the manufacturer to conduct a trial blending using your commonly used fertilizer raw materials (such as the organic fertilizer granules and compound fertilizer powder from your factory) for 10 consecutive batches. Record the deviation of each batch and confirm whether it meets your quality requirements.

The "convenience" of equipment operation: Observe whether the controller interface is easy to understand (such as Chinese display, one-click recipe invocation), and whether it supports "data export" (such as USB flash drive export of ingredient records for convenient quality inspection traceability), to avoid "complicated operation and workers' reluctance to use it".

The "compatibility" of the workshop environment: Measure whether the size of the measuring equipment fits the space of your factory workshop (such as height and width), and whether the power supply voltage (such as 380V/220V) and air source pressure (if pneumatic devices are needed) are compatible, to avoid the situation of "buying it but not being able to install it".

Summary: Three "Don't Buy" Principles

Do not purchase if the static accuracy is over 0.2% and the dynamic accuracy is over 2% (it cannot guarantee that the fertilizer nutrients meet the standards).

Do not purchase products with core components (sensors, motors, frequency converters) of unknown brands and without warranty (high maintenance costs and short lifespan in the long run).

We won't purchase from manufacturers that have no case history in the fertilizer industry and do not offer on-site installation and commissioning services (poor compatibility and no after-sales guarantee).

By screening through the above standards, it is possible to effectively avoid "inferior equipment" and select a fertilizer dynamic batching machine with high precision, strong stability and suitable for one's own production.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.