HOME > News > Industry News > Why does the organic fertilizer fermentation and blending machine need regular maintenance?

HOME > News > Industry News > Why does the organic fertilizer fermentation and blending machine need regular maintenance? Update time : 2025-09-10 Publisher:Zhengzhou Hanke Machinery

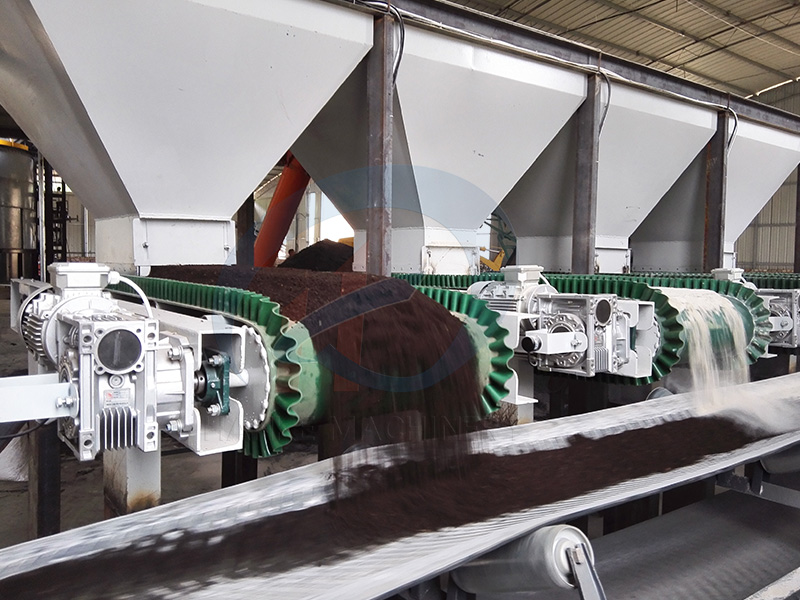

The organic fertilizer fermentation fertilizer blending machine (referred to as "organic fertilizer blending machine") requires regular maintenance. The core of this requirement is determined by the characteristics of the materials it processes (high humidity, high viscosity, and containing impurities) and the operating principle of the equipment (dynamic blending and precise measurement). The essence of maintenance is to prevent problems such as material residue, component wear, and accuracy decline from affecting the service life of the equipment and the quality of the blended fertilizer, ultimately ensuring production efficiency and the quality of organic fertilizer products. The specific reasons can be elaborated from the following four key dimensions:

I. Avoid "material residue blockage" to prevent equipment from getting stuck or damaged.

The materials after organic fertilizer fermentation have the characteristics of high humidity (usually with a water content of 30% - 60%), high viscosity and easy to form lumps. Moreover, they may be mixed with coarse fiber impurities such as straw, mycelium residue and livestock and poultry manure. During the operation of the fertilizer blending machine, the following problems may occur:

Residual accumulation: Materials tend to adhere to the inner walls of the batching bin, the blades of the screw conveyor, and the surface of the metering sensor. If not cleaned for a long time, it will form "hard scale", causing the batching channel to narrow or even get blocked.

Equipment jamming: If hard lumps or coarse fibers get entangled around the transmission components (such as the motor shaft, stirring paddle), it will increase the motor load. In severe cases, it may cause the motor to overload and burn out, or the transmission gears to break.

Material deterioration: The remaining organic fertilizer in the equipment (in a dark and sealed environment) is prone to secondary fermentation or mold growth. When blending fertilizer subsequently, it will contaminate the new materials, resulting in moldy organic fertilizer products and imbalanced nutrients.

Regular maintenance (such as cleaning the residue on the silo wall and unblocking the conveying pipelines) can directly prevent the above problems and ensure the continuous and stable operation of the equipment.

II, maintain "precise batching accuracy" to ensure that the nutrient content of organic fertilizers meets the standards.

The core function of the organic fertilizer blending machine is to dynamically measure and mix different raw materials according to the preset formula (such as the ratio of nitrogen, phosphorus, potassium and organic matter), and the accuracy directly determines whether the product meets agricultural standards (such as NY 525-2021 "Organic Fertilizer"). If not maintained, the accuracy will rapidly decline.

Failure of metering components: If residual materials adhere to the surface of weighing sensors (such as pressure sensors, weighing modules), it will cause "zero drift", resulting in "deviation between the actual dosing amount and the set value" (for example, if 10% of the bacterial agent is set to be added, only 5% is actually added).

Wear of transmission components: After long-term wear of the blades of the screw conveyor and the rollers of the belt conveyor, it will cause unstable material conveying speed (sometimes fast and sometimes slow), further disrupting the batching ratio.

Valve sticking: If the discharge valves of the raw material silo (such as pneumatic butterfly valves or gate valves) are stuck by sticky materials, they may not close tightly or open fully, resulting in raw material leakage or insufficient supply, which directly disrupts the formula ratio.

Regular maintenance (such as calibrating sensors, replacing worn blades, and cleaning valves) can ensure that the batching accuracy error is controlled within ±1% - 3% (industry qualified standard), avoiding product scrapping or agricultural yield reduction due to nutrient non-compliance.

III. Extend the "service life of core components" and reduce equipment replacement costs

The core components of the organic fertilizer blending machine (motor, reducer, weighing sensor, screw conveyor) are all high-value and easily damaged parts. If they lack maintenance for a long time, it will accelerate the aging of the components.

Motors and reducers: Material dust or sticky impurities can easily enter the motor bearings and reducer gearboxes, leading to lubrication failure and causing "abnormal bearing noise" and "gear wear". The normal service life can be shortened from 5-8 years to 2-3 years, and the replacement cost can be as high as several thousand yuan.

Weighing sensor: It is a precision electronic component. If residual materials press on the sensor for a long time, it will cause "linear distortion" (unable to accurately perceive weight changes). The replacement cost is usually between 1,000 and 3,000 yuan per piece.

The long-term friction between the blades and the casing of a screw conveyor (especially when the material contains coarse fibers) can cause the blades to become thinner and the inner wall of the casing to wear. If not promptly repaired by welding or replaced, it will result in "material leakage" and a decline in conveying efficiency by more than 50%.

Regular maintenance (such as adding grease to motor bearings, cleaning and changing oil in reducers, checking the force state of sensors, and repairing worn blades) can extend the lifespan of core components by 30% to 50%, significantly reducing long-term equipment investment costs.

IV. Ensuring "Production Safety" and Avoiding Personal or Equipment Accidents

When the organic fertilizer blending machine is in operation, it involves "mechanical transmission" and "electrical control". If maintenance is lacking, it can easily lead to safety hazards.

Mechanical safety: If the protective covers of the transmission components (such as belts and gears) become loose due to vibration, or if the inlet of the screw conveyor is blocked by hard residues, the operator may accidentally touch the moving parts during the cleaning process, resulting in cuts or entanglement injuries.

Electrical safety: If the electrical circuits inside the equipment (such as sensor signal lines and motor power lines) are corroded by dust or damp materials, a "short circuit" may occur, causing a trip or even a fire.

Equipment overload: If the batching bin is blocked and not detected in time, the motor will be in an overloaded state for a long time, which may cause the motor to burn out and even lead to overheating and fire in the distribution box circuit.

Regular maintenance (such as checking the fixation of protective covers, cleaning dust from electrical cabinets, and testing overload protection devices) can eliminate the aforementioned safety hazards, comply with standards such as "Mechanical Safety - General Design Principles" (GB/T 15706), and ensure the safety of operators and the production environment.

Conclusion: Regular maintenance is the key to "reducing costs, improving quality and ensuring safety".

The maintenance of organic fertilizer blending machines is not an "extra cost", but a "necessary investment" to ensure production. Through regular cleaning, calibration, lubrication, and component inspection, three core values can be achieved: ① Ensuring blending accuracy and guaranteeing the quality of organic fertilizer products; ② Extending the service life of the equipment and reducing replacement costs; ③ Eliminating safety hazards and avoiding production accidents. It is generally recommended that the maintenance cycle be as follows: daily cleaning (once per shift), component lubrication (once a week), precision calibration (once a month), and core component inspection and repair (once a quarter). Editor's share

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.