HOME > News > Industry News > Configuration parameters of the 4-tank biological agent batching machine and how much a set is sold

HOME > News > Industry News > Configuration parameters of the 4-tank biological agent batching machine and how much a set is sold Update time : 2025-09-12 Publisher:Zhengzhou Hanke Machinery

The 4-bin biological agent batching machine is an automated batching equipment specially designed for powder and granular materials such as biological agents, organic fertilizers, and compound fertilizers. Through independent weighing in four bins and an intelligent control system, it achieves precise proportioning and efficient mixing of multi-component materials. The following is an introduction from three aspects: core configuration, technical parameters, and price range

I. Core Configuration Parameters of the 4-tank Biological Agent Batching Machine

Storage silo system: Four independent storage silos are adopted, with each silo body typically having a capacity of 0.5 to 2 cubic meters. The materials selected are 304 stainless steel or carbon steel with plastic coating, which have strong corrosion resistance. The silo is equipped with pneumatic butterfly valves or screw feeders, supporting rapid material discharge and anti-clogging design.

Weighing and measurement module: Each warehouse is equipped with a high-precision curved beam pressure sensor under it, with a weighing range of 0-1000kg and an accuracy of ±0.2%. It supports both dynamic and static dual-mode weighing. The system is equipped with an automatic drop correction function, which can eliminate the influence of the inertia of material falling on the measurement accuracy.

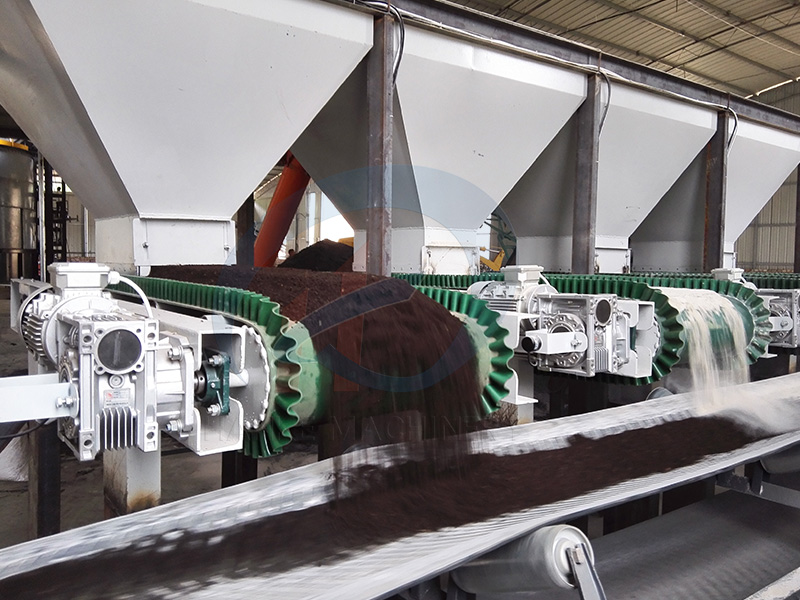

Mixing and conveying unit: Equipped with a horizontal mixer or a double-shaft paddle mixer, with a stirring capacity of 1-3 cubic meters and adjustable speed (30-150 revolutions per minute), ensuring uniform mixing of materials within 10-30 seconds. The mixed materials are conveyed to the packaging stage by belt conveyors or screw conveyors.

Intelligent control system: It adopts Siemens PLC or industrial-grade microcomputer control, supporting touch screen operation and remote monitoring. The system can store more than 20 groups of formulas, and is equipped with automatic calibration, fault alarm, data recording and MODBUS communication interface, which can be seamlessly integrated with ERP or MES systems.

Ii. Technical Parameters of the 4-Tank Biological Agent Batching Machine

Power supply requirements: 380V/50Hz, total power approximately 15-30kW(including motor, sensor, etc.).

Environmental adaptability: Operating temperature -10℃ to 50℃, humidity ≤85%, suitable for complex working conditions such as dust and humidity.

Safety protection: Equipped with explosion-proof motor, overload protection device and emergency stop button, it complies with the GB/T 16754-2021 safety standard.

Structural configuration: Standard configuration includes 4 vertical silos (with selectable volume, such as 500L per silo), and each silo bottom is independently equipped with a high-precision metering screw (single or double screw), driven by servo or variable frequency motors to ensure feeding accuracy.

Iii. Price Range and Influencing Factors of 4-Tank Biological Agent Batching Machine

The price of the 4-tank biological agent batching machine varies significantly due to differences in configuration, brand and production capacity

Economical equipment: Priced at approximately 60,000 to 150,000 yuan, it is suitable for small-scale biological agent production lines. It is equipped with a basic weighing module and manual control, with a production capacity of about 1 to 3 tons per hour.

Standard type equipment: Priced at approximately 180,000 to 300,000 yuan, it adopts PLC control, stainless steel silo and high-efficiency mixer, with production capacity increased to 3 to 8 tons per hour, and supports multi-formula switching.

High-end customized equipment: Priced over 350,000 yuan, it integrates automatic packaging machines, dust removal systems and Internet of Things modules, with a production capacity of over 10 tons per hour. It is suitable for large-scale agrochemical enterprises or export projects.

Typical case

A 4-bin batching machine purchased by a certain biotechnology company in Shandong Province is equipped with a 304 stainless steel bin, Siemens PLC and a double-shaft mixer, with a total price of 280,000 yuan. It achieves precise proportioning of bacterial agents, humic acid and fermentation materials, increasing production efficiency by 40%.

A certain organic fertilizer factory in Henan Province has selected economical equipment priced at 120,000 yuan. By combining pneumatic butterfly valves with screw feeders, it meets the demand for low-cost expansion.

Zhengzhou Hanke Machinery offers direct sales from stock. Our equipment is directly available to everyone, making it more economical and cost-effective. Welcome to call 17319777703 for consultation and understanding, and visit our factory for on-site inspection and tour.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.