HOME > News > Industry News > In a 10-ton-per-hour organic-inorganic compound production line, under what circumstances is a dynam

HOME > News > Industry News > In a 10-ton-per-hour organic-inorganic compound production line, under what circumstances is a dynam Update time : 2025-09-30 Publisher:Zhengzhou Hanke Machinery

In a 10-ton-per-hour organic-inorganic compound fertilizer production line, the choice between dynamic scales and loss-in-weight scales mainly depends on the characteristics of your materials, the precision requirements for batching, and the budget. There is no absolute good or bad between the two of them; it's just a matter of whether they are suitable or not.

I. Under what circumstances is it suitable to choose a dynamic scale (belt scale)?

Dynamic scales are suitable for continuous and rapid batching of single, bulk materials with formula ratio requirements that are not "extremely precise".

Applicable scenarios

1. As the main ingredient of the "base material" : In your compound fertilizer production line, if there is one or two raw materials with a very large proportion (such as organic fertilizer fermentation material accounting for more than 50% of the total formula, or a single nitrogen, phosphorus and potassium raw material with a large proportion), it is very suitable to use a dynamic scale. Its primary task is to "feed steadily and in large quantities" to ensure the smooth operation of the production line.

2. Stable physical properties of materials and good fluidity: The particles of the materials are uniform, not prone to moisture absorption, non-sticky, and have good fluidity. Such materials will not adhere to the belt, ensuring continuous and stable discharging.

3. Limited budget or space constraints: The structure of dynamic scales is relatively simple, and the initial investment and later maintenance costs are usually lower than those of loss-in-weight scales. Meanwhile, it also occupies a relatively small height space.

4. In situations where absolute precision requirements are not extreme: The formula of compound fertilizers itself has a certain tolerance, especially for the mixing of macronutrients. The precision of dynamic scales (usually ±0.5%-1%) is completely acceptable in most cases, as long as the total nutrient content of the final product meets the standards.

A brief summary: When you need to handle bulk main materials "quickly and steadily" and the precision requirement is not extremely high, choose a dynamic scale. It is the "main conveyor officer" of the production line.

Ii. Under what circumstances must a loss-in-weight scale be selected?

The loss-in-weight scale is suitable for batching trace amounts of materials that are expensive or have extremely high requirements for formula precision. It controls the amount of feed by constantly measuring the "loss" of the entire feeding bin (including the material and the scale body), which is a true "weight reduction method" measurement with extremely high precision.

Applicable scenarios

1. Adding "core materials" and "trace components" : This is the most typical application of a loss-in-weight scale. For example, you need to add:

Expensive trace elements (such as boron, zinc, iron, etc.)

A small amount of functional additives (such as bacterial agents, growth regulators).

High-concentration chemical fertilizers (such as potassium dihydrogen phosphate in small amounts but with high nutrient content, etc.).

These materials are used in small quantities but are of high value. Every little less added may affect the fertilizer efficiency, and every little more will waste costs. The high precision of the weightless scale (usually up to ±0.1%-0.5%) plays a significant role here.

2. Material properties are "difficult to handle"

Extremely poor fluidity: for instance, particularly fine, easily bridging, and fluffy organic fine powder.

Prone to moisture absorption and caking: Materials tend to stick to the warehouse walls.

Unstable density: The tightness of the material varies greatly.

For these "troublemaking" that dynamic scales find hard to handle, loss-in-weight scales can achieve stable and precise feeding through overall weighing and advanced stirring/arch-breaking devices.

3. Extremely strict formula requirements: When your product standards are very high or customers have extremely strict requirements for fluctuations in nutrient content, the entire production line (or main sections) can use loss-in-weight scales for batching to ensure the best product consistency and quality.

A simple summary: When you need to "precisely control expensive or difficult-to-handle trace components" and pursue the ultimate stability of product quality, choose a loss-in-weight scale. It is the "precision blender" of the production line.

Iii. Best Practice Suggestions for a 10-ton-per-hour Organic-Inorganic Compound Production Line

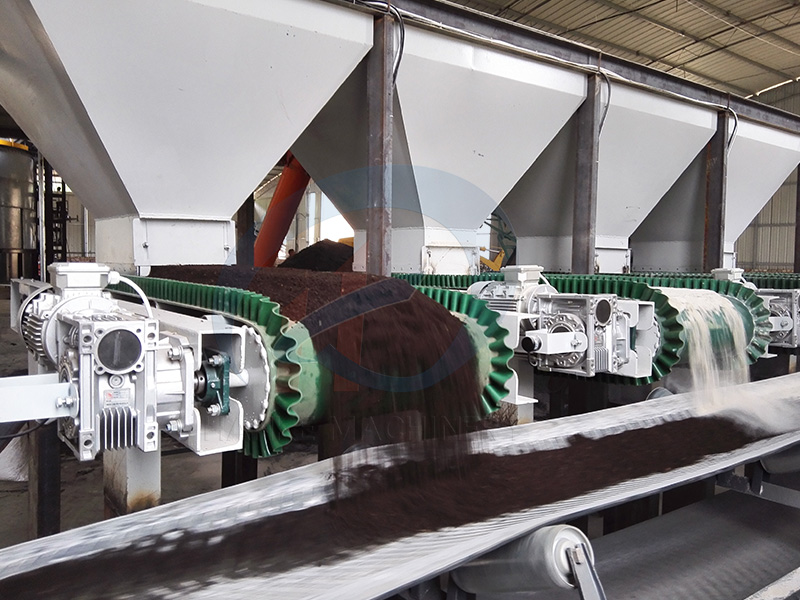

For a production line of organic-inorganic compound fertilizer with an output of 10 tons per hour, the most economical and efficient solution is often the combined use of "dynamic scales + loss-in-weight scales".

Dynamic scales are responsible for processing bulk basic raw materials (such as organic fertilizers, potassium chloride, large-particle urea, etc.).

The weightless scale is responsible for adding trace core raw materials (such as trace elements, monoammonium phosphate, bacterial agents, etc.).

This combination method not only takes advantage of the stability and low cost of dynamic scales when handling large flow materials, but also leverages the high precision and difficult material handling capabilities of loss-in-weight scales in micro-batching, achieving a perfect balance between cost and accuracy.

To sum up in one sentence:

For large volume, full capacity and stable transportation, choose a dynamic scale.

To be meticulous and precise, choose a loss-in-weight scale.

Adults don't make choices. Smart designers of organic-inorganic compound production lines will have the two of them work together.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.