HOME > News > Industry News > Zhengzhou Hanke Machinery: Expert in Quantitative Packaging Equipment for Bulk Materials, Covering C

HOME > News > Industry News > Zhengzhou Hanke Machinery: Expert in Quantitative Packaging Equipment for Bulk Materials, Covering C Update time : 2025-10-14 Publisher:Zhengzhou Hanke Machinery

As a leading manufacturer specializing in quantitative packaging equipment and batching control systems, Zhengzhou Hanko Machinery, with its in-depth understanding of the characteristics of materials in various industries such as chemicals, grains, and coal, has developed the XZK series, XZF series, and XZLX series of dedicated packaging machines to address the packaging challenges of bulk materials including bentonite (powder and granular). These machines achieve the core values of "precise measurement, efficient packaging, and wide application scenarios", effectively solving the efficiency and cost issues in the packaging process of bulk materials for enterprises.

I. Core Product Matrix: Three series to meet the packaging needs of bulk materials such as bentonite.

The three specialized series of packaging machines from Zhengzhou Hanko Machinery are designed to address the characteristics of bentonite, such as its tendency to absorb moisture and form lumps and generate dust, as well as the significant differences in flowability of bulk materials. Through differentiated designs, they meet the requirements of different production capacities and process scenarios.

1.XZK Series: High-Efficiency Intelligent Bulk Material Packaging Machine - Suitable for Medium and High Capacity Scenarios

Core positioning: Targeting the "continuous packaging" needs of small and medium-sized factories, emphasizing "efficiency + intelligence", especially suitable for bulk packaging of powder / fine granular materials such as bentonite and kaolin.

Core advantages:

Accurate measurement: Equipped with high-precision weighing sensors (accuracy ±0.2%), combined with the "spiral variable frequency feeding + secondary feeding" technology, it avoids overfeeding of materials and ensures that the weight error of each bag is controllable.

Anti-dust design: Sealed filling port + external dust removal fan, reducing dust leakage during bentonite powder packaging, meeting the environmental protection requirements of the workshop, and protecting the health of operators at the same time.

Efficiency Leading: Each single unit can complete 20-30 bags (500-2000kg per bag) packaging per hour, and it supports seamless connection with upstream material storage tanks and conveyor belts to achieve continuous feeding and automatic packaging.

This product is suitable for bentonite production lines in the chemical industry and powder material packaging workshops in the building materials industry. It is especially suitable for medium and large enterprises with a daily packaging volume of over 500 tons.

2. XZF Series: Multi-functional and Economical Bulk Material Packaging Machine - Suitable for Medium and Small Production Capacities and Multiple Material Scenarios

Core positioning: Balancing "cost-effectiveness and multi-functionality", it can flexibly switch between packaging different types of bulk materials such as bentonite, grains (like corn and wheat), and coal (granular coal), meeting the "one machine, multiple uses" demands of small and medium-sized factories.

Core advantages:

Flexible material compatibility: By replacing the "feeding device", it can be compatible with multiple materials - when packaging powder materials such as bentonite, "screw feeding" is used; when packaging granular coal and grains, it switches to "vibration feeding", without the need to purchase dedicated equipment separately, reducing initial investment.

Simple operation: Equipped with a liquid crystal touch screen, it allows for visual setting of parameters such as packaging weight and speed. Novices can quickly get the hang of it, reducing personnel training costs.

Durable structure: The body is made of thickened steel, and the parts in contact with materials are made of stainless steel (anti-corrosion and easy to clean), which is especially suitable for long-term use with materials such as bentonite that may contain trace impurities.

The most cost-effective scenario is for small-scale bentonite processing plants in towns and townships, comprehensive grain purchasing points, and small coal transfer stations, where the daily packaging volume is between 100 and 300 tons.

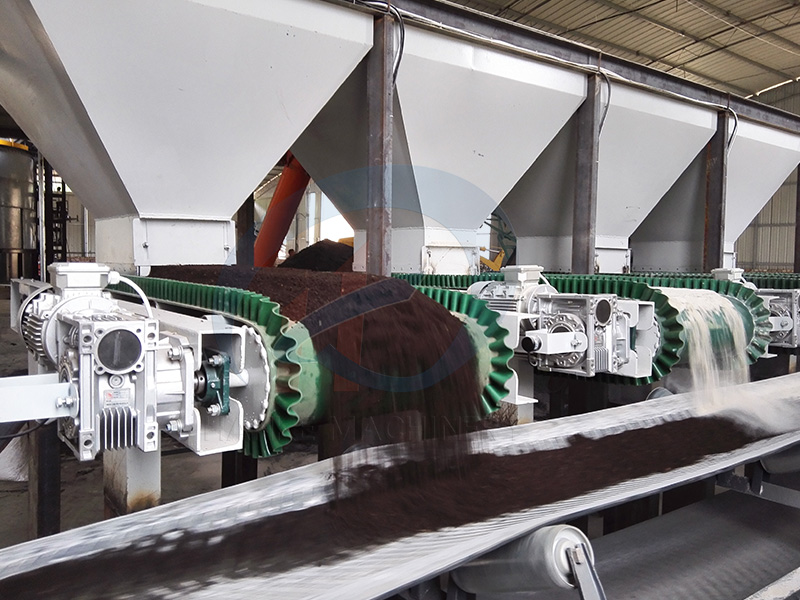

3. XZLX Series: Large-scale Conveyor-Type Bulk Material Packaging Machine - Suitable for Large-scale and Integrated Production

Core positioning: Focusing on the demand of large enterprises for "fully automated production lines", it can integrate the full-process functions of "automatic bagging, quantitative filling, bag mouth sealing, and palletizing", achieving "unmanned operation" for the packaging of bulk materials such as bentonite.

Core advantages:

Full-process automation: Equipped with a mechanical bag-grabbing device, it automatically grabs and secures ton bags. After packaging, it is connected to a palletizing robot via a conveyor belt. The entire process requires no human intervention, significantly reducing labor costs (by over 80% of packaging workers).

High production capacity ceiling: Each production line can complete 30-50 bags (1-2 tons per bag) of packaging per hour, and supports parallel operation of multiple units (such as 2-3 XZLX series devices running simultaneously), meeting the ultra-large-scale packaging demand of over 1,000 tons per day.

Intelligent Monitoring: Equipped with an integrated PLC control system, it can monitor the equipment's operational status in real time (such as weighing data and fault alarms), and supports integration with the enterprise's ERP system to achieve an integrated "packaging data - inventory management" solution, facilitating production scheduling.

Applicable scenarios: Large-scale bentonite production bases of chemical groups, national-level grain reserve depots, and large-scale coal washing and processing enterprises, where deep integration with the entire production line is required in large-scale scenarios.

II. Core Competitiveness: Multi-domain Adaptability + Customized Services, Addressing Industry Pain Points

Cross-industry experience empowerment: Zhengzhou Hanko Machinery has been deeply engaged in the chemical, grain, and coal industries for many years, familiar with the characteristics of bulk materials in different industries (such as the corrosiveness of bentonite in the chemical industry, the fluidity of grains, and the abrasiveness of coal). When designing equipment, it fully considers the special needs of each industry (such as explosion-proof design in the chemical industry and anti-mold materials in the grain industry).

Outstanding customization capabilities: In response to the specific needs of enterprises (such as non-standard ton bag specifications, special material moisture content / particle size, and workshop space constraints), we can provide "exclusive solution design" - for example, installing "heating anti-caking devices" for customers with high-humidity bentonite, and optimizing the equipment footprint for customers with small workshops to ensure that the equipment is perfectly adapted to the actual production environment.

Full-cycle service guarantee: We offer "pre-sale selection guidance (recommending series models based on production capacity and material characteristics) + in-sale installation and commissioning (on-site guidance for equipment installation and integration with production lines) + post-sale maintenance and repair (regular inspections and prompt response to fault repairs)", eliminating the worries of enterprises. It is especially suitable for continuous production scenarios with high requirements for equipment stability.

III. Applicable Customers and Cooperation Suggestions

Recommended customers: Bentonite / Kaolin production enterprises in the chemical industry, grain processing and storage enterprises, coal washing and transfer enterprises, and powder material (such as gypsum powder, lime powder) manufacturers in the building materials industry.

For cooperation consultation: If you need to know the detailed parameters of a certain series of equipment (such as power, floor space, applicable material particle size range), real-time quotations, or arrange for a sample machine inspection, you can directly contact the business team of Zhengzhou Hanko Machinery. Provide "material type + packaging specification (weight per bag) + daily production capacity demand", and you will receive a customized solution.

Zhengzhou Hanko Machinery, with the core philosophy of "Focusing on quantitative packaging and empowering efficient production", provides precise solutions for bulk material packaging needs of different scales and industries through its three series of specialized equipment: XZK, XZF, and XZLX. It helps enterprises reduce costs, increase efficiency, and enhance the level of production automation.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.