HOME > News > Industry News > Composition, Core Functions and Price of the 5-bin Dynamic Blending Machine for Compound Fertilizer

HOME > News > Industry News > Composition, Core Functions and Price of the 5-bin Dynamic Blending Machine for Compound Fertilizer Update time : 2025-10-20 Publisher:Zhengzhou Hanke Machinery

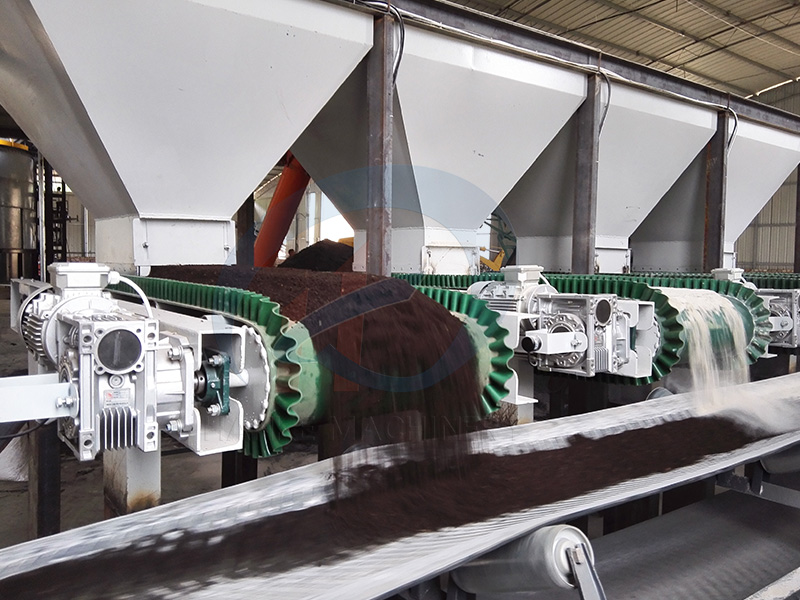

The 5-bin dynamic batching machine for compound fertilizer is a device used in the compound fertilizer production process to automatically weigh, batch and convey five different raw materials. It features high precision, high efficiency and a high degree of automation. Here is a detailed introduction:

I. Equipment Composition of the 5-bin Dynamic Blending Fertilizer Mixer

Raw material silos: Usually there are five, made of stainless steel, with brackets embedded in the concrete structure for easy connection and fixation. Each silo is also equipped with a raised partition to prevent material from flowing over during discharging, and at the same time, it can increase the capacity of the silo.

Automatic feeding device: There are 5 sets, all made of stainless steel structure. They adopt multi-stroke cylinders and pneumatic switchable feeding doors, featuring two feeding modes: fast feeding and slow feeding. The size and structure of the feeding doors can be specifically designed according to the fluidity and proportion of each material.

Scale hopper: 1 piece, with an upper square and lower circular structure, generally with a volume of 0.7 cubic meters, made of stainless steel.

Load cells and their suspension systems: Four sets of stainless steel load cells and their suspension systems for accurately measuring the weight of materials in the scale hopper.

Weighing system support frame: 1 set, connecting the weighing suspension system and supporting the scale hopper.

Weighing hopper door opening and closing mechanism: 1 set, stainless steel structure, with pneumatic switch for material door to achieve the discharge and closure of the weighing hopper.

Electric control box and electrical control system: 1 set. The electric control box is made of stainless steel, sealed and waterproof as well as dustproof. The batching system completes the batching of each material in sequence and according to the set weight.

II. Core Functions and Features of the 5-bin Dynamic Blending Machine for Compound Fertilizer

Precise multi-material proportioning: Supports automatic proportioning of 5 different materials according to preset formulas, with positioning accuracy up to ±10mm. Real-time display and adjustment of weighing data are available.

Intelligent formula management: Allows input, storage, and modification of formulas, with data confidentiality features to prevent unauthorized copying and downloading.

Full-process automation: From material location, sealed connection, dust collection to historical data query and report printing, the entire process requires no human intervention.

Adaptation to harsh environments: The equipment is designed to handle industrial environments with dust, humidity, etc., and is suitable for fields such as refractory materials, chemical engineering, and biomedicine.

III.What is the price range of the 5-bin dynamic batching machine for compound fertilizers?

The price of a 5-bin dynamic batching machine for compound fertilizers varies depending on factors such as the brand, configuration, and degree of automation of the equipment. Generally, the price range is from 15,000 yuan to over 60,000 yuan. For example, the dynamic batching bin from Zhengzhou Hank Technology Machinery Packaging Machinery Factory is priced at 15,000 yuan per set.

Welcome more users to visit, consult and order equipment at Zhengzhou Hanko Machinery. Contact number: 17319777703!

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.