HOME > News > Industry News > How to purchase a dynamic batching machine for nutrient soil? Attached are some purchasing suggestio

HOME > News > Industry News > How to purchase a dynamic batching machine for nutrient soil? Attached are some purchasing suggestio Update time : 2025-10-23 Publisher:Zhengzhou Hanke Machinery

When purchasing a dynamic batching machine for nutrient soil, in addition to considering the price and customization services, it is also necessary to conduct a comprehensive assessment from multiple aspects such as production demands, equipment quality, and after-sales service. Here are some detailed purchasing suggestions:

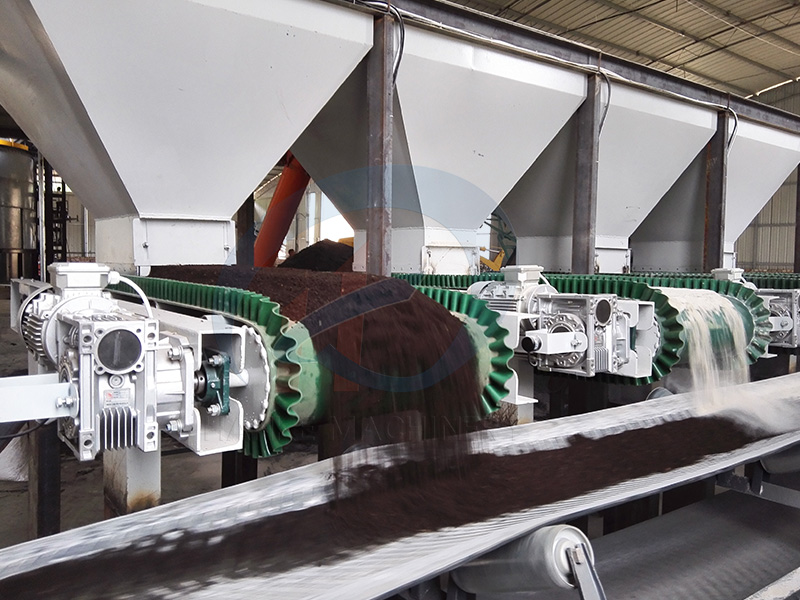

Clarify production requirements: Select equipment models based on your production scale, types of raw materials, and complexity of the formula. For instance, small enterprises with lower initial production capacity requirements can choose equipment with a smaller hourly batching capacity; while large-scale production enterprises need to select equipment with fast batching speed and multi-bin systems to meet the demands of large-scale production. At the same time, consider the physical properties of raw materials, such as moisture content and viscosity. For high-moisture materials, a dedicated pretreatment system may be required.

Pay attention to equipment quality: Choose brands with good reputation, mature production experience and good customer feedback. High-quality equipment is more strict in material selection and manufacturing process, such as using 304 stainless steel for the inner wall of the mixing chamber and wear-resistant manganese steel for the paddle blades, which can ensure the durability and stability of the equipment and reduce the probability of faults.

Examine the measurement accuracy: Prefer equipment with a weighing error of ≤±0.5%. High-precision batching can ensure the stable quality of fertilizer products, meet the strict requirements of different formulas for raw material ratios, and avoid quality issues of fertilizers caused by inaccurate batching.

Consider the degree of automation: Equipment with a high degree of automation can achieve the automation of processes such as batching and mixing through PLC or industrial computer control systems, reducing manual intervention, lowering labor intensity, and simultaneously enhancing production efficiency and accuracy. For instance, some equipment features automatic feeding, proportioning, and stirring control functions, which can automatically adjust the feeding speed of each material and stirring parameters according to preset formulas.

Evaluate after-sales service: Choose suppliers that can provide comprehensive after-sales service, including installation and commissioning, technical training, and long-term maintenance. Good after-sales service can ensure that problems encountered during the installation and use of equipment are resolved promptly, guaranteeing the normal operation of the equipment, reducing downtime and production losses.

Pay attention to energy efficiency and environmental performance: Modern organic fertilizer production has increasingly strict environmental requirements. Equipment should have good dust control and noise reduction measures, and at the same time, choose equipment with lower energy consumption, such as high-efficiency motors and optimized conveying systems, to reduce energy consumption and environmental pollution during the production process.

On-site inspection of equipment: Before making a purchase, it is advisable to conduct an on-site inspection of the equipment manufacturer's production capacity and technical strength, observe the actual operation of the equipment, understand the ease of operation and maintenance convenience of the equipment, and also check the usage effect and operational stability of the equipment at other users' sites.

When purchasing equipment, it is important to choose the right model and manufacturer. It is advisable to select a manufacturer with strong capabilities to ensure the rights of users. If you want to buy a dynamic batching machine for nutrient soil, you can come to visit Zhengzhou Hankemechanical. We offer direct sales from the manufacturer with favorable prices, lower than the market rate. Our company has professional engineers to tailor production plans for you. We guarantee high output and efficiency for your production. Welcome to click for free consultation or come to our factory for selection.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.