HOME > News > Industry News > Organic inorganic compound fertilizer 5 warehouse dynamic automatic batching scale customer case sce

HOME > News > Industry News > Organic inorganic compound fertilizer 5 warehouse dynamic automatic batching scale customer case sce Update time : 2025-02-22 Publisher:Zhengzhou Hanke Machinery

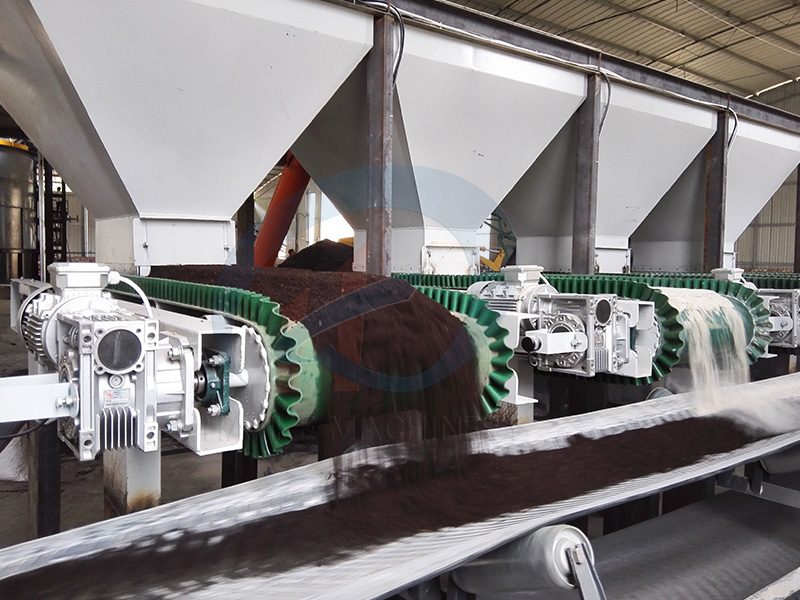

Case background:Organic and inorganic compound fertilizer is a kind of fertilizer mixed with organic and inorganic fertilizer in a certain proportion, which can provide quick nutrients and improve soil structure, and has been widely used in agriculture in recent years. In order to achieve efficient and accurate production, many fertilizer manufacturers have begun to use 5-bin dynamic automatic batching scale systems. This system can realize the automatic weighing, batching and mixing of various raw materials, which greatly improves the production efficiency and product quality.

The following is a typical application case background of an Inner Mongolia customer:

Enterprise type: Medium fertilizer production enterprise.

Product type: organic and inorganic compound fertilizer.

Types of raw materials: organic raw materials (such as livestock manure, straw, etc.) and inorganic raw materials (such as urea, diammonium phosphate, potassium chloride, etc.).

Production demand: It is necessary to automatically mix 5 different raw materials in a set proportion and achieve continuous production.

Solution: Adopt 5 warehouse dynamic automatic batching weighing system.

Equipment features:

The 5-bin dynamic automatic batching scale system is an efficient and accurate automation equipment with the following features:

1. Multi-warehouse design:

The system is equipped with 5 separate feedstock silos, which can handle 5 different feedstocks simultaneously.

Each bin is equipped with a separate feeding device (such as a screw feeder or vibrating feeder) for precise control.

2. Dynamic weighing:

High precision weighing sensor is used to achieve dynamic continuous weighing and high batching accuracy (usually up to ±0.2%).

Suitable for powder or granular materials with good fluidity.

3. Automatic control:

Equipped with PLC (Programmable logic controller) and touch screen man-machine interface, easy to operate.

A variety of formulas can be preset and switched with one click to meet the production needs of different products.

4. Efficient mixing:

After the dosing is completed, the material is automatically transported to the mixer to achieve even mixing.

High mixing efficiency and good mixing uniformity.

5. Strong durability:

The main parts of the equipment are made of stainless steel or wear-resistant materials, corrosion resistance, wear resistance, long service life.

6. Strong flexibility:

The number of silos can be expanded according to production needs (such as upgrading to 6 silos, 8 silos, etc.).

Suitable for a variety of materials (such as fertilizer, feed, chemical raw materials, etc.) ingredients.

5 warehouse dynamic automatic batching scale system is a modern fertilizer production attention equipment, can achieve efficient, accurate, automatic batching and mixing, to help enterprises improve production efficiency and product quality. If you have related needs, it is recommended to professional, good technology, strong manufacturers, such manufacturers organic inorganic compound fertilizer 5 warehouse dynamic automatic batching scale quality can be guaranteed, service can be in place, in order to better create benefits for users, Zhengzhou Hanke Machinery is such a manufacturer, the majority of users invest in organic inorganic compound fertilizer 5 warehouse dynamic automatic batching scale, You can come to Zhengzhou Hanke machinery to have a look.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.