HOME > News > Industry News > Selection criteria for animal feed screw packaging machine manufacturers

HOME > News > Industry News > Selection criteria for animal feed screw packaging machine manufacturers Update time : 2025-04-15 Publisher:Zhengzhou Hanke Machinery

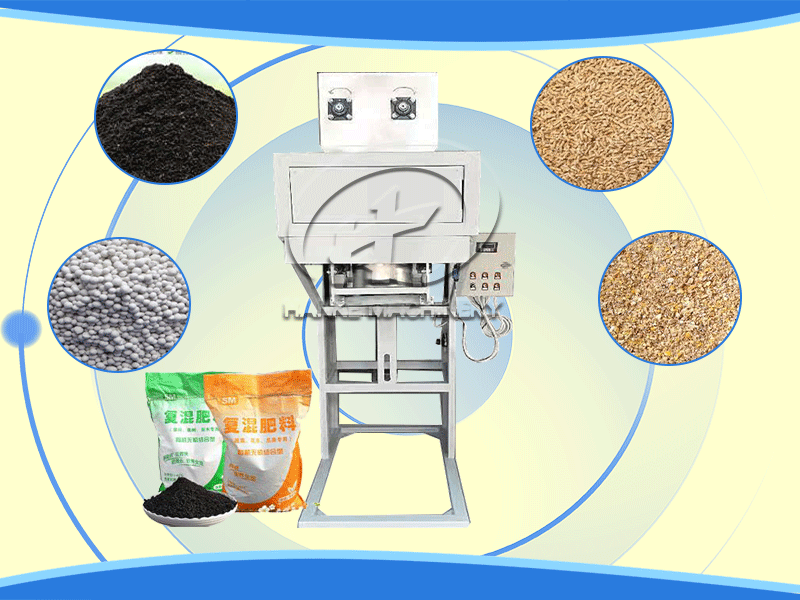

The animal feed screw packaging machine is a screw weighing, discharging and filling machine, which is usually suitable for powder and small granular animal feed. It integrates multiple functions such as electronic weighing, automatic bag opening and dust removal. There are many manufacturers of animal feed screw packaging machines in the market. So how to choose a manufacturer? The following text will introduce it to you.

Selection criteria for animal feed screw packaging machine manufacturers

Consider production capacity based on actual demand.

Choose a screw-type quantitative packaging scale with spare production capacity. This can not only ensure the achievement of production volume but also meet production requirements. If the production scale is large and the demand for production capacity is high, it is recommended to choose large-scale equipment, which is more convenient to operate and can better match the rhythm of large-scale production.

Clarify the packaging specifications and output requirements for animal feed. For instance, determine the weight range of each bag of feed (such as the common 5 - 50Kg, etc.) and the number of bags that need to be packaged per hour or per day, so as to screen out manufacturers that can meet the production scale.

Pay attention to the cost performance of the equipment.

Expensive equipment does not necessarily mean good quality. One should choose a screw-type quantitative packaging scale within their budget that offers good value for money. It is advisable to compare the prices, configurations and performances of the same type of equipment from different manufacturers and make a comprehensive assessment of the cost-effectiveness.

Examine the professionalism and strength of the manufacturer.

Professional background: It is recommended to choose from professional packaging machine equipment manufacturers. Professional manufacturers focus on the packaging machine field, with more mature technology and better quality assurance for their products. For example, Anhui Xinyuan Packaging Technology Co., Ltd. is a national high-tech enterprise specializing in the research and development, manufacturing, sales and service of automatic production lines for various forms of materials such as powder, granules and fluids, including automatic batching, mixing, metering, packaging, boxing and palletizing.

On-site inspection: If time permits, you can visit the manufacturer on-site to have a direct understanding of its production scale, production process, R&D capabilities, etc., thereby better assessing the manufacturer's strength.

Evaluate the quality of after-sales service

Quality inspection: Understand whether the manufacturer has a strict quality inspection process before leaving the factory. For instance, Anhui Xinyuan Technology has professional quality inspection personnel to debug and test each product before it leaves the factory. This can ensure the quality of the equipment from the source.

Commissioning and installation: Inquire with the manufacturer about their response time and service content for equipment commissioning and installation. For instance, Xinyuan Technology promises to respond within 24 hours after the customer has prepared the required materials and notified them. The commissioning personnel will arrive at the machine location within the fastest 24 hours. In cases of inconvenient transportation or long distances, they will also arrive and commission the product within 72 hours.

Operation training: Confirm whether the manufacturer provides operation training services to ensure that the operators can master the usage and maintenance skills of the equipment proficiently. For instance, the commissioning personnel of Xinyuan Technology need to train the operators of the customers until they can operate independently.

Warranty and maintenance: Pay attention to the warranty period and maintenance policies of the equipment. For instance, some manufacturers offer a one-year warranty and lifetime maintenance, charging only the cost price for replacement parts during repairs. This can reduce the equipment's usage cost in the long run.

Understand the equipment's applicability and technical specifications.

Applicable materials: Ensure that the manufacturer's screw packaging machine is suitable for powdery or small granular materials such as animal feed. Common animal feeds like pet food, fish feed, chicken feed, and pig feed all require the packaging machine to be capable of precise measurement and packaging.

Technical indicators: Pay attention to the basic parameters of the packaging machine, such as packaging range, packaging speed, and measurement accuracy. For example, the packaging range of a screw-type quantitative packaging scale is generally 5 - 50Kg, the packaging speed is 180 - 240 bags per hour, and the allowable error is ±2‰, etc.

Conclusion: When choosing a manufacturer of animal feed spiral packaging machines, it is necessary to consider your own needs and not make a blind choice. Zhengzhou Hanko Machinery Manufacturer looks forward to your call.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.