HOME > News > Industry News > Which type of automatic feeding bin is better for the seedling substrate production line

HOME > News > Industry News > Which type of automatic feeding bin is better for the seedling substrate production line Update time : 2025-10-05 Publisher:Zhengzhou Hanke Machinery

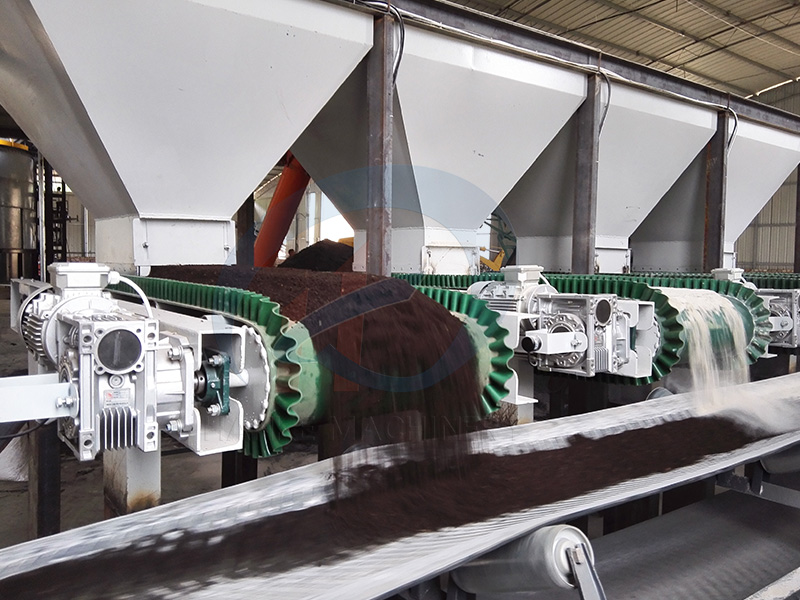

For production scenarios where the raw materials for seedling substrate are diverse (such as peat, vermiculite, perlite, organic fertilizer, etc.), the proportioning requirements are precise, and it is prone to generating dust, Zhengzhou Hanke Machinery analyzes for you which type of automatic feeding bin should be selected for the seedling substrate production line.

For large-scale seedling factories, it is recommended to choose multi-bin dynamic batching machines (such as the HK-DPL series from Zhengzhou Hanke Machinery). This equipment supports continuous feeding and automatic control. Its core parameters include batching accuracy of ±1%, a 10m³ large-capacity material bin, and PLC formula storage function. It can simultaneously process more than 10 types of materials, meeting the requirements of high-precision measurement, multi-material mixing, and continuous production. The parts of the equipment that come into contact with materials are made of 304 stainless steel, which has corrosion resistance. The integrated stirring device can prevent material stratification and improve the mixing efficiency. Its silo supports customization of 3 to 8 positions, catering to different formula requirements such as vegetable seedling raising and flower substrate. The dynamic batching capacity reaches 5 to 20 tons per hour, significantly reducing batch-to-batch errors.

Small and medium-sized seedling factories can choose static batching machines or modular equipment (such as the HK-JPL series of Zhengzhou Hanke Machinery) to reduce the initial investment cost. This type of equipment adopts a 3-5 chamber design, with an accuracy of ±2%, and supports manual/automatic dual-mode switching, flexibly adapting to small-scale production scenarios. If the raw materials contain impurities or corrosive substances, models with integrated vibrating screens or filtration devices should be given priority, and it is necessary to ensure that the contact surfaces are made of 304 stainless steel.

When selecting an automatic seedling substrate mixing bin, the following parameters should be given key consideration:

Powder accuracy: For light materials such as peat and perlite, it should be within ±2%.

Formula flexibility: The number of silos should cover common substrate formulas (such as 3-5 types of vegetable seedlings and 5-8 types of flower substrates).

Corrosion resistance: 304 stainless steel is preferred for the contact surface to avoid chemical corrosion.

Capacity matching: Select dynamic batching equipment of 5 to 20 tons per hour or static equipment with lower capacity based on daily output.

see details +

see details +

see details +

see details +

Tel:+86 17319777703

Tel:+86 17319777703

E-mail:hkautomaticpack@foxmail.com

E-mail:hkautomaticpack@foxmail.com

Address:Xingyang City, Zhengzhou City, Henan Province.

Address:Xingyang City, Zhengzhou City, Henan Province.

Privacy Policy Copyright © Zhengzhou Hanke Machinery Equipment Co., Ltd Co., Ltd.